| |

Servovalve

Operation

A servovalve is a flow control device that mechanically

controls hydraulic flow over a large range of flow rates

and fluid pressures. A servovalves is controlled by

a small electrical input current signal which causes

the torque motor to rotate a rigid flapper toward one

of the nozzles. The resulting pressure differential

at the two ends of the spool moves the spool to open

or close ports. There is a positional feedback device

called “feedback flex” that returns the

flapper to the center position and balances the forces

on the spool. The system reaches steady-state operation

when the port openings are adjusted such that the fluid

flow through the servovalve matches the flow rate specification

by the electrical input current signal. To summarize,

a servovalve compares the hydraulic flow rate to the

electrical input current signal, and automatically adjusts

the servovalve port openings until the desired flow

rate is achieved. Servovalves respond very quickly to

input current signal, and can have a useable frequency

range of up to 150 Hz.

Servovalve

Tests

The servovalve tests are intended to check for defect

and evaluate servovalve performance. The types of servovalve

test are briefly described. The four general categories

of tests include: (1) Flow Gain: Flow rate versus input

current, (2) Pressure Gain: Load pressure versus input

current, expressed in psi/mA, (3) Null Leakage: Valve

internal leakage flow rate versus input current and

(4) Dynamic Response: Sinusoidal input current of varying

frequency versus the displacement of a low-mass low-friction

actuator. The solenoid valves, shown in Figure 7, can

either be closed or open to change the testing condition.

The servovalve tests that were specified for the project

are the following.

Blocked

Port Pressure

For this test, the solenoid valves

to control ports C1 and C2 are closed. After opening

the solenoid valve in the pressure return line

R, the solenoid valve in the pressure supply line

P is opened. The port abbreviations C1, C2, R,

and P refer to the schematic from Figure 7. Input

current control signal is then swept between plus

and minus rated current values, stopping at zero

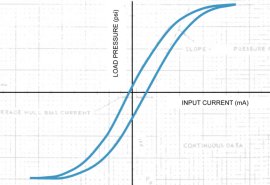

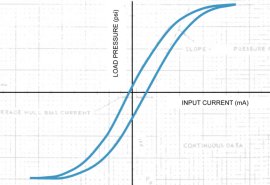

input current. For the Pressure Gain plot, load

pressure versus the input current is measured,

recorded, and plotted. Typical Pressure Gain plot

produced from the blocked port pressure test is

shown in Figure 10.

|

Figure

10. Typical servovalve Pressure Gain

plot

|

The blocked port pressure test simulates an actuator

applying force on a very stiff specimen or performing

a high pressure test on a hydraulic tube or fitting.

Since there is no external device attached to the servovalve,

any anomalous behavior in the hysteresis plot curve

is an indication that there is something wrong with

the servovalve. The blocked port pressure test provides

the clearest indication of a servovalve malfunction,

while the other tests evaluate its performance.

Blocked Port Pressure at Null

At null condition, ports C1 and C2 are blocked but a

small flow is still possible from the pressure port

P to the return port R through the flapper nozzles.

The blocked port pressure at null test can measure the

degree of wear in the valve. An ideal valve has half

the supply pressure on the output ports at null. In

practice this pressure is usually a little higher than

the half pressure point.

Open Port Flow

For this test, the solenoid valves to control ports

C1 and C2 are fully open. Input current control signal

is then swept between plus and minus rated current values,

and the flow meters FM1 and FM2 measures the flow rate

in the hydraulic lines. The flow rate versus the input

current plot can be used to evaluate servovalve performance

such as Flow Gain, linearity, symmetry, hysteresis,

and saturation. The open port flow test simulates an

actuator applying a force on a very flexible and compliant

specimen or position control with minimal load and friction.

Again, since there is no external device physically

connected to the servovalve in the test, any anomalous

behavior is an indication of servovalve malfunction.

Null Leakage

At null condition, there is a small flow from the pressure

port P to the return port R through the flapper nozzles.

The internal leakage flow can be measured using the

flow meter FM3 (shown in Figure 7). The null leakage

test simulates a double-ended actuator holding zero

force. This test can indicate the degree of wear in

the servovalve.

Frequency Response

The frequency response test examines the dynamics characteristics

of the servovalve. The servovalve is a dynamic device

that is frequently used to the full extent of its bandwidth.

Used in conjunction with a feedback signal (such as

position or force), the servovalve can be used to create

a closed-loop servo, controlling the position or force

of an actuator. For servovalves to be used effectively

in closed-loop mechanical systems, their frequency response

must be thoroughly characterized throughout their usable

bandwidth. A servovalve that is stable with a 3,000

psi supply pressure may not be stable when the pressure

is raised to 5,000 psi. The frequency response test

is run with no load (all control ports solenoid valves

opened) and a sinusoidal current input signal is swept

through the servovalve with varying frequencies. A low-mass,

low-friction actuator is used in FRA (shown in Figure

7) attached to a LVDT to measures the displacement of

the actuator. The resulting plots are the Bode magnitude

and phase shift plots. These two graphs plot output/input

amplitude versus input frequency and output/input phase

shift versus input frequency.

It is often not necessary to perform every one of these

servovalve tests. If the performance of a servovalve

deviates from expected behavior in one of these tests,

the servovalve will likely require service from the

manufacturer.

Hydraulic

Power Supply Operation

The United Filco hydraulic power supply is rated at

3,000 psi and 35 gpm. The fluid velocity coming out

of the hydraulic power supply is about 25 fps. ME 5.3

located the necessary hoses and fittings to connect

the hydraulic power supply to the test bench. Hoses

with a 3,000 psi working pressure and 0.75 inch inside

diameter were used to connect the hydraulic power supply

to the test bench. The component testing group primarily

uses a petroleum-based hydraulic fluid. Many components

in commercial aircrafts use Skydrol phosphate-ester

based hydraulic fluid, which meets FAA specifications

for function and safety. Skydrol hydraulic fluid poses

a greater health hazard and is substantially more expensive

than petroleum-based fluids. ME 5.3 used a petroleum-based

Mobil DTE 25 hydraulic fluid for the servovalve calibration

project.

Sensors

and Control Hardware

The test bench is equipped with four types of measuring

devices. There are three Cox internal turbine flow meters

(FM1~3), two Sensotec A-5 series pressure transducers

(PT1~2), a linearly variable differential transducer

(LVDT) for frequency response test, and a Ohio Semitronics

current transducer that measures the control signal

to double check the input current signal.

Flow meters FM1 and FM2 measures the flow rate in the

+ Flow and the – Flow line. The internal turbine

flow meter (Cox Model ANC 16), shown in Figure 11, outputs

a digital pulse train at 10 VDC. The frequency of that

pulse train signal corresponds to the amount of fluid

flow through the body of the flow meter. It is shown

that the flow rate ranging from 0 to 60 gpm corresponds

to pulse train signal frequency of 0 to 1400 Hz. A separate

and different flow meter FM3 (Cox Model ANC 8-4) is

used to measure the leakage flow rate.

Figure

11. Cox internal turbine flow meter

|

Figure

12. Sensotec pressure transducer

|

Pressure transducers PT1 and PT2, shown in Figure 12,

are linear analog voltage devices with output voltage

proportional to pressure. The Sensotec A-5 Gage series

pressure transducer, shown in Figure 10, is rated at

5000 psi and outputs 0-5 VDC. LVDT and the current transducer

are also both linear analog voltage devices with output

voltage proportional to displacement and current, respectively.

The current transducer will be discussed in more complete

detail in sections on hardware interface development.

For controlling the

servovalve tests, five normally closed Parker

solenoid valves (SOL1~5), shown in Figure 13,

manage the flow of hydraulic fluid through the

test bench. By selectively open and close solenoid

valves, the user can configure the test bench

for any of the required servovalve tests. For

subsequent data acquisition, ME 5.3 obtained pin-out

diagrams for the pressure transducers and the

flow meters.

|

Figure

13. Parker solenoid valves

|

National

Instruments DAQ Card

Boeing required ME 5.3 to use a National Instruments

(NI) DAQ card for the servovalve calibration project.

ME 5.3 narrowed its search to two models, an older E-Series

and a new M-Series model DAQ card. After researching

the advances in NI DAQ cards and consulting with our

liaison engineer, a NI-PCI 6221 M-Series DAQ card was

chosen for the project. The M-Series cards support all

of the functions needed for the project and cost less

than the E-Series cards. Since the M-Series cards are

relatively new, ME 5.3 reviewed the technical documentation

extensively. The M-Series DAQ card supports C++, LabView,

Visual Basic, and Microsoft .Net programming languages.

The specifications of the NI-PCI 6221 are tabulated.

Two

16-bit analog outputs (833 kS/s)

NI-MCal calibration technology

NIST-traceable calibration certificate

NI-DAQmx Measurement Services to simplify configuration

&measurements

Correlated DIO (8 clocked lines, 1 MHz)

24 digital I/O; 32-bit counters; digital triggering |

ME 5.3 also selected NI BNC 2090 DAQ breakout

panel, shown in Figure 12, since it has the same pin

capabilities and supports all the functions of the NI-PCI

6221 M-Series DAQ card. A breakout panel is easier to

use than hooking up wire leads directly to the DAQ card.

The BNC-2090 is a shielded, rack-mount adapter with

signal-labeled BNC connectors, spring terminal blocks,

and component locations for passive signal conditioning.

The BNC-2090 consists of 22 BNC connectors (18 analog,

2 digital, and 2 user-defined), a 68-pin male connector,

and 28-spring terminals to provide easy connection.

The panel also has signal conditioning capabilities

(simple passive, low pass or high pass filter, voltage

attenuator circuits).

Figure

12. BNC 2090 DAQ breakout panel

Software

In the Request for Proposal, Boeing requested a Windows-based

software for the control and data acquisition portion

of the Servovalve Calibration Project. C++ was selected

as the programming language since it is fully supported

by the M-series DAQ card and is a common programming

language. During the research phase of software development,

National Instruments provided extensive documentation

and example programs to demonstrate the capabilities

and codes recognized by the DAQ card. In addition, other

C++ programming books were referenced in order to gain

sufficient knowledge and skills to explore the full

potential of the DAQ card.

Install

and Test DAQ and Breakout Panel

The installation of the NI DAQ card was straightforward,

due primarily to NI’s extensive support for their

DAQ card and breakout panel. NI measurement devices

and application software NI-DAQ 7.x was installed on

the computer. The software includes two NI-DAQ drivers:

NI-DAQmx and traditional NI-DAQ. These drivers have

an Application Programming Interface (API) which includes

a library of functions, classes, and properties for

creating applications. NI-DAQmx is used with Windows

2000/NT/XP, LabVIEW, Measurement Studio 7.x, or Measurement

Studio .Net.

Since a computer was used for the project, ME 5.3 selected

a Peripheral Component Interconnect (PCI) card. PCI

is a local bus standard developed by Intel Corporation

which connects directly to the microprocessor. This

is not to be confused with PCI-X (PCI extended) which

is an enhanced version of PCI and was designed jointly

by IBM, HP and Compaq to increase performance of high

bandwidth devices. The NI-PCI-6221 card is installed

into a PCI slot in the computer.

The BNC-2090 breakout panel comes ready to use. The

break out panel was installed on the equipment rack

under the computer and then connected to the card using

a SHC68-68-EPM cable. The SHC68-68-EPM cable is an extended

performance shielded cable designed specially for the

M-Series DAQ card that allows connection to standard

68-pin accessories. The application software automatically

installed the software Measurement & Automation

Explorer (MAX) to confirm, test, and configure the NI-DAQ

card settings. MAX also has its own software-based test

panel for troubleshooting the DAQ card.

Next

Page - Software Development

|

|