Hardware

Interface Development

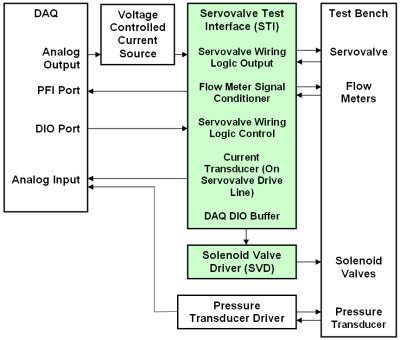

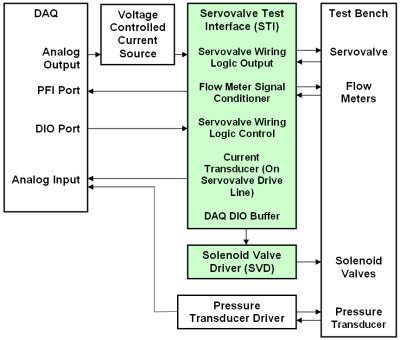

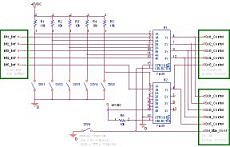

After considering multiple design solutions, a hardware

interface system was designed to both condition input

signals to the DAQ and amplify output signals to hardware.

Most signal conditioning occurs in the Servovalve Test

Interface (STI) while the solenoid valves are controlled

by the Solenoid Valve Driver (SVD). Pressure transducers

are driven by external hardware provided by Boeing,

and the servovalve voltage controlled current source

is also external, but connects directly to the Servovalve

Test Interface. The signals processed by the hardware

interface are shown in the signal flow diagram in Figure

20.

Figure

20. Servovalve hardware interface signal flow

diagram

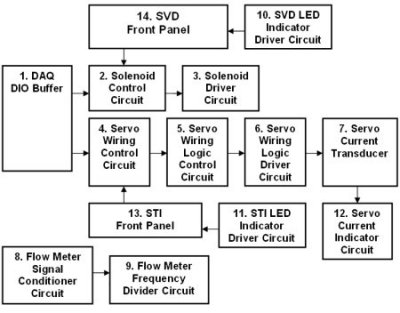

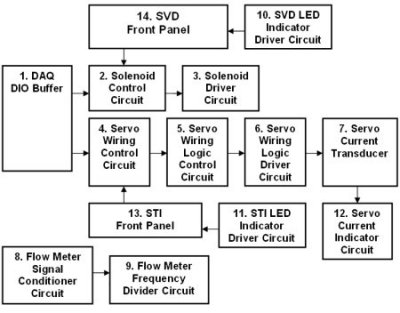

The components designed primarily by

ME5.3 are the Servovalve Test Interface and the Solenoid

Valve Driver (in green). Multiple subsystems are present

in the Servovalve Test Interface and the Solenoid Valve

Driver as they accomplish a variety of signal processing

tasks. The main components in the circuitry are shown

below in Figure 21. Each component is examined in detail

in the following section.

Figure

21. Circuitry

components in STI and SVD

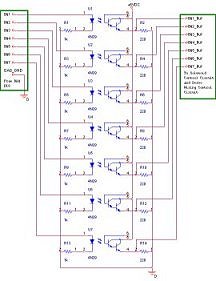

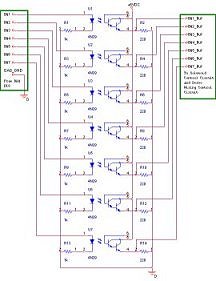

| 1.

DAQ DIO Buffer

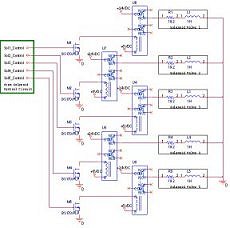

This circuit component shown in Figure 22 is

designed to isolate the DAQ DIO ports from the

interface hardware. All channels are digitally

isolated with 4N29 optoisolators. All inputs are

0-5 V logic signals from the DAQ breakout box.

The optoisolators are able to source up to 10

mA of current to the rest of hardware interface

circuitry.

2.

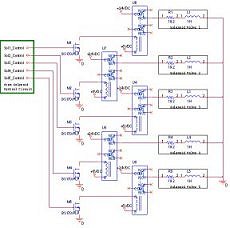

Solenoid Control Circuit

The solenoid control circuit shown in Figure

23 selects between a computer signal from the

DIO buffer circuit and a manually created signal

on the Solenoid Valve Driver front panel to send

to the solenoid driver circuit. |

Figure

22. DAQ DIO buffer circuit schematic

Figure

22. DAQ DIO buffer circuit schematic |

| The circuit either reads bits

1 through 5 from the DIO Buffer or monitors the

position of five SPST switches on the front panel

of the Solenoid Valve Driver.Depending on the

position of the manual override switch on the

front panel, the circuit selects between a manual

signal or computer signal to send to the solenoid

driver circuit. |

|

Figure

23. Solenoid control circuit schematic |

Data selection is

implemented using two 74157 IC’s. The IC’s

can accept up to two sets of four inputs and select

a single set of four based on the logic state

of the SELECTAB input. Outputs of this circuit

go to the solenoid driver circuit to control the

state of the five solenoid valves on the test

bench and to the Solenoid Valve Driver LED indicator

driver circuit for display of solenoid and manual

override states. |

|

3.

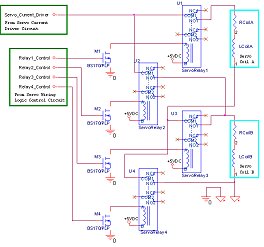

Solenoid Driver Circuit

The solenoid driver circuit shown

in Figure 28 reads the selected control bits for

the solenoids from the solenoid control circuit

and uses five relays to control the state of each

solenoid. The control bits for the solenoids cannot

provide sufficient current to activate the relays,

so a BS170 n-channel enhancement mode MOSFET is

used to drive each relay. The relays are encased

in small PCB mount packages and are activated

with a 5 V 40 mA signal. Each is capable of driving

up to 2 A of DC current. Power for the solenoid

valves is provided by an independent 24 VDC power

supply that can source up to 10A of current. Each

solenoid valve requires 1.25 A of current to open,

which requires the solenoid power supply to be

able to source at least 6.25 A.

|

Figure

24. Solenoid driver circuit schematic

|

4.

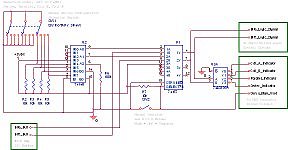

Servovalve Wiring Control Circuit

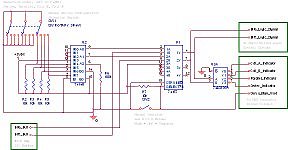

Wiring configuration, shown in Figure 25, can be controlled

by either a two bit signal from the DAQ DIO buffer circuit

or manually by a rotary selector switch on the Servovalve

Test Interface front panel. As with the solenoid control

circuit, a SPST switch on the front panel controls the

SELECTAB input of a 74157 data selector IC. Depending

on the state of the switch, either the manual or computer

control signal is selected. To conserve outputs on the

DAQ DIO port, only two bits are used to control servovalve

wiring configuration. The rotary selector switch on

the front panel effectively creates a four bit signal

with the two bits worth of information. For data selection

to occur the signal must be encoded into a two bit signal.

|

Figure

25. Servovalve wiring control circuit

schematic |

Encoding is accomplished using a 74148 priority

encoder IC. This IC can encode up to eight inputs

into a three bit signal. As only two bits are

needed, four of the inputs are tied high and

the most significant bit of the output is ignored.

The output is thus a two bit signal with the

same form as the signal from the DIO buffer.

|

After data selection, the two bit signal is passed

to the servo logic control circuit. Also, through the

use of a 74LS139 IC, the signal sent to the logic control

circuitry is decoded and sent to the Servovalve Test

Interface LED indicator driver circuit. This allows

the state of the wiring configuration to be indicated

on the front panel. The state of the manual override

switch is also sent to the LED driver circuit so that

its state is shown on the front panel.

5.

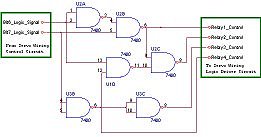

Servovalve Wiring Logic Control Circuit

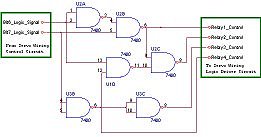

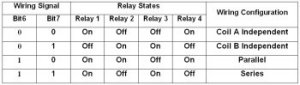

Servovalve wiring logic control diagram is shown in

Figure 26. Each servovalve has two coils that are used

to drive the torque motor. As there are two independent

coils, there are four possible different wiring configurations:

Coil A independent, Coil B independent, Coil A and Coil

B in parallel, and Coil A and Coil B in series. Each

configuration is used in practice for different control

situations. The user can control the wiring configuration

with a two bit signal sent from the DAQ DIO port or

with a manual signal from a selector switch on the front

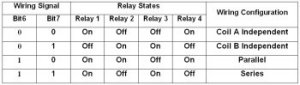

panel. The table below summarizes the wiring states

associated with the bit states.

Figure

26. Servovalve wiring logic control

Figure

26. Servovalve wiring logic control

circuit schematic |

Table.

Servovalve wiring states/bit states

|

Control of the wiring states is implemented through

the use of a digital logic circuit consisting entirely

of NAND gates. The gates in use are of the 7400 series

TTL logic family. If part replacement or board replication

is ever necessary, the components in this circuit are

intentionally chosen to be easy to find and replace

at a low cost. The NAND gates receive the two bit signal

from the DIO port and decode the signal into control

signals for four relays.

Logic circuit design consisted of creating an individual

Karnaugh map to define the states of each relay control

signal as a function of the input bits. The result was

a sum of products form logic equation for each relay

state. The sum of products form is easily transferable

into purely NAND states, and after simplification the

resulting logic circuit is shown in the schematic above.

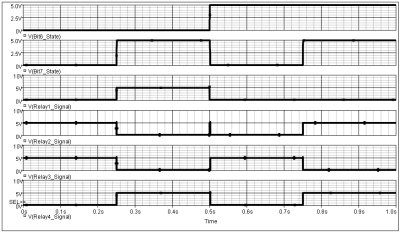

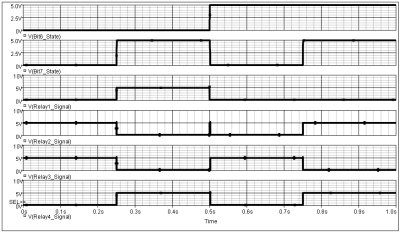

The timing diagram, shown in Figure 27, summarizes

the output of the logic circuit. Note that the relays

are on when the timing diagram is at 0 V and off when

the diagram is at 5 V. Comparison of the relay states

with the desired states in the logic table above shows

that the circuit functions as desired. Hardware testing

provides the same result. Also note that during transitions

some voltage spikes are present. These spikes are not

an issue because the response time of the relays is

far slower than the transition time of the logic signal

from the DIO port. Also, all tests are conducted with

a single, preset wiring configuration. Transitions do

not occur during tests so there is no possibility of

adverse effects from transition timing.

Figure 27. Wiring logic timing diagram

6.

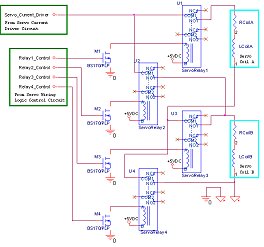

Servovalve Wiring Logic Driver Circuit

Wiring state is controlled by four relays as

shown in Figure 28. The 7400 series chips in

the servo wiring control circuit cannot provide

enough current to drive the relays directly,

so an intermediate amplifier is in use. BS170

n-channel enhancement mode MOSFET’s are

used to amplify the logic signal. No special

power requirements are necessary as all components

are driven by a common 5 V power supply. The

current signal for the servovalve coils is provided

by an external current source in the Boeing

Servo Controller II.

|

Figure 28. Servovalve wiring

logic driver circuit schematic

|

|

Figure 29. Servovalve current

transducer

|

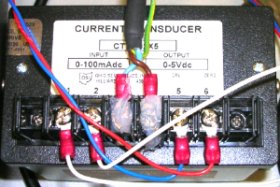

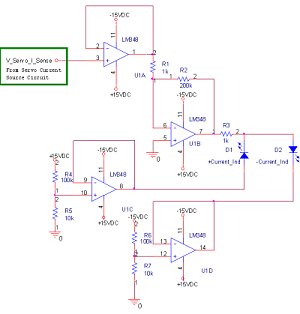

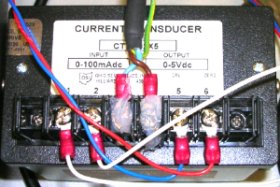

7.

Servo Current Transducer

The servo current transducer shown in Figure

29 is an off-the-shelf device that provides

a 0-5 V analog voltage signal that is linearly

proportional to the electrical current that

flows through it. It is placed in series with

the servovalve coils to monitor servovalve current.

|

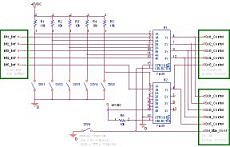

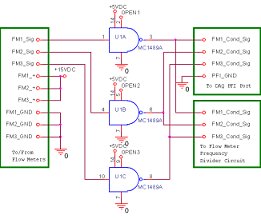

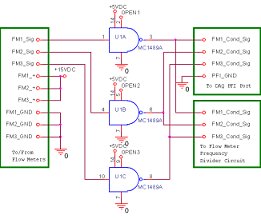

| 8.

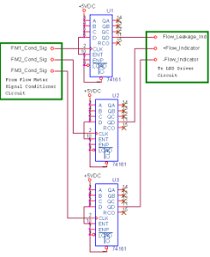

Flow Meter Signal Conditioner

Flow meter signal conditioning,

shown in Figure 30, is implemented through the

use of an MC1489A line driver IC’s. This

IC can receive input signals that range from -30

V to +30 V and converts the signal to a TTL level

logic signal. The conversion point can be programmed

with a resistor placed from the supply voltage

to pin number two. The default transition point

(no external resistor) is approximately 2.5 V.

The three flow meters on the test bench output

a 0-10 V pulse train, so the default transition

point is adequate. Output signals are sent to

the DAQ PFI port where counters are used to measure

the frequency of the pulse train and thereby measure

flow rate. Outputs are also sent to a frequency

divider circuit for front panel display purposes. |

Figure

30. Flow meter signal conditioner

circuit schematic

|

|

Figure

31. Flow meter frequency divider

circuit schematic

|

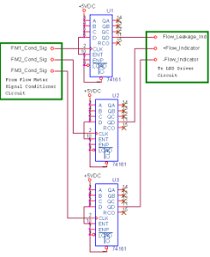

9.

Flow Meter Frequency Divider Circuit

Three LED’s on the front

panel of the Servovalve Test Interface are used

to provide a visual indication of flow in the

test bench. The LED’s flash when the flow

meters are measuring a flow. The drive signal

for the LED’s is derived from the pulse

train output of the flow meters. Unfortunately,

the frequency of the flow meters at high flow

rates is 600-800 Hz, which is far too fast for

the human eye to notice. As a solution to this

problem, the frequency of the pulse train is

divided by 16 using the 74161 four bit synchronous

binary counter IC. This makes the flash frequency

of the indicators at high flow rates around

40 Hz which is approximately the upper end of

the visual range. The circuit schematic is shown

in Figure 31.

|

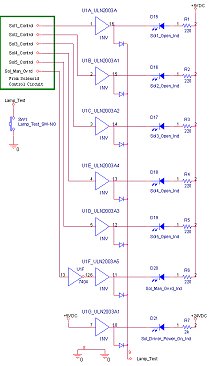

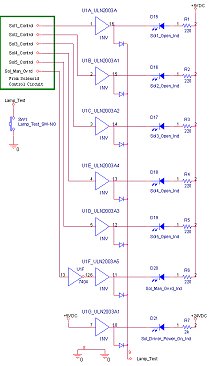

| 10.

Solenoid Valve Driver LED Indicator Driver Circuit

LED’s on the front panel of the Solenoid

Valve Driver are all driven by a single ULN2003A

Darlington array IC. This IC acts as an inverting

open-collector buffer for digital logic signals.

The IC is necessary because TTL IC’s used

in the interface circuitry are unable to provide

enough current to both drive indicators satisfactorily

while still driving other logic IC’s. As

an added advantage, the ULN2003A has a common

diode protected lamp test line. When this line

is brought to ground, all LED’s connected

to the IC will light so the user can see if any

lamps are not functioning properly. The lamp test

button can be found on the front panel. A schematic

of that system is shown in Figure 32. |

Figure

32. Solenoid Valve Driver LED

indicator driver circuit schematic

|

The manual override signal that is input to this circuit

is low when the manual override function is activated.

LED’s are turned on by the ULN2003A with a high

signal on the input line, thus for a manual override

indicator to function correctly on the front panel,

the signal must be inverted prior to reaching the LED

driver IC. This is accomplished with an inverter in

a 7404 IC as shown).

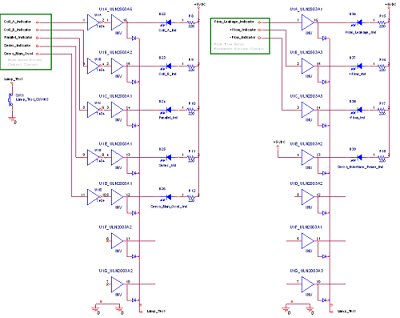

11.

Servovalve Test Interface LED Indicator Driver Circuit

LED’s on the Servovalve Test interface are driven

in the same way as on the Solenoid Valve Driver, as

shown in Figure 33. The ULN2003A IC’s provide

a common collector output with lamp test function to

drive all digital indicators. Similarly to the manual

override signal for the Solenoid Valve Driver, the manual

override signal for the servovalve wiring configuration

and the wiring state indicators are all active low signals.

The inputs are inverted prior to reaching the LED driver

with five inverters in a 7404 inverter IC. All other

signals are active high and are sent directly to the

inputs of the LED driver IC.

Figure 33. Servovalve

Test Interface LED indicator driver circuit

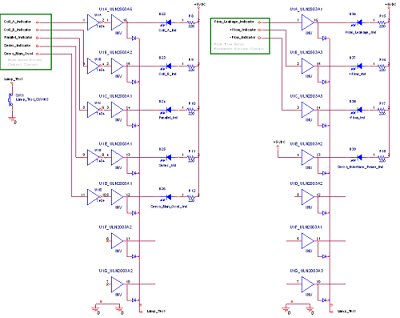

12.

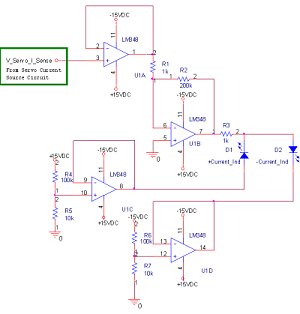

Servovalve Current Indicator Circuit

The user of the Servovalve Test Interface is provided

with two LED’s on the front panel that indicate

the magnitude and direction of current flow in the servovalve,

as shown in Figure 32. The circuit schematic is shown

in Figure 34. One LED is used to indicate positive current

flow and the other indicates negative. The brightness

of the LED’s corresponds to the amount of current

flowing in the servovalve. The LED’s are designed

to reach maximum brightness when 20mA of current is

flowing through the servovalve, which is reasonable

for nearly all servovalve tests. The four op amps in

an LM348 IC are used to create this circuit. The first

op amp, U1A, buffers the current signal so that the

LED indicator circuit will not interfere with the current

signal sent to the analog input of the DAQ. U1B is an

inverting amplifier calibrated such that the supply

voltage will appear at the amplifier’s output

when 20mA of current are flowing through the servovalve.

U1C and U1D provide DC offsets for the two indicator

LED’s so that their response is more linear. The

LED’s used require about 1.7V of forward voltage

before they will light, so the two DC offset amplifiers

are designed to provide almost that much offset (approximately

1.6V). Note that these LED’s will not respond

to the lamp test function because they are controlled

by an analog signal. Their signal cannot be sent through

the ULN2003A IC’s because it is a digital line

driver, not analog.

Figure 34. Servovalve current indicator circuit

schematic

13.

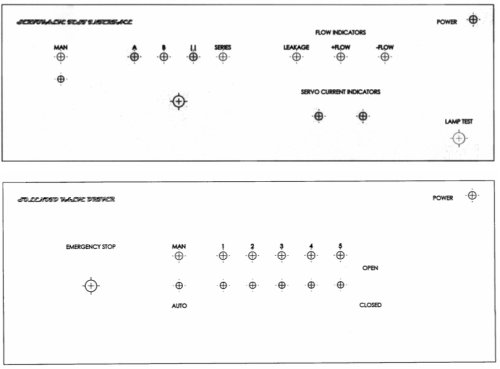

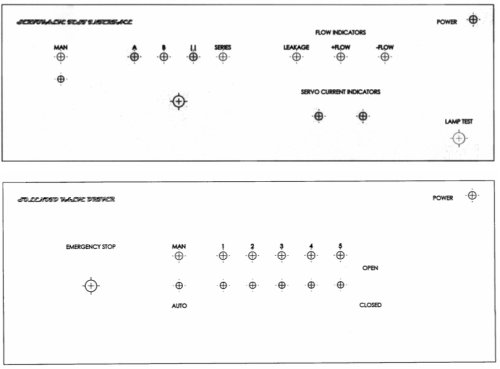

Servovalve Test Interface Front Panel

The front panel layout of the Servovalve Test Interface

and Solenoid Valve Driver can be seen in Figure 35.

All functions are described in detail with the accompanying

schematic diagram in the previous section.

Figure 35. (Top) Servovalve Test Interface

Front Panel

(Bottom) Solenoid Valve Driver Front Panel

Next Page -

Pictures and Endnote

|