| |

BACKGROUND

Boeing Commercial Airplanes is a major supplier of

commercial aircraft flown throughout the world. The

complexity of modern aircraft necessitates Boeing to

have large component testing facilities. The high load

and the high rate at which the loads are applied required

the use of hydraulically powered systems. To accurately

control these hydraulic powered systems, servovalves

are used in many aircraft component testing applications.

Servovalves are high power-gain mechanical flow control

devices that operate on a small electrical input current.

The servovalve input current control signal is approximately

50 mA max, while the hydraulic output can be as high

as 3000 psi at 35 gallons per minute (gpm). The fluid

flow rate through a servovalve is approximately linearly

proportional to the electrical input current control

signal. For a mechanical device that delivers such large

fluid flow, a servovalve has a significant bandwidth,

capable of operating up to 150 Hz.

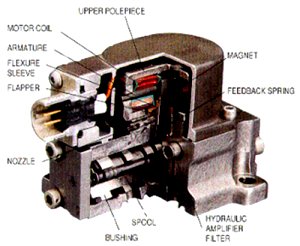

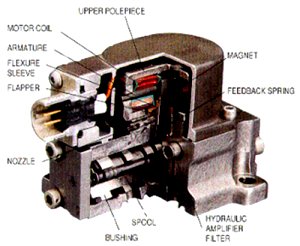

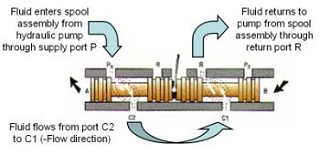

A cut-away view of a Moog 30 Series

servovalve is shown in Figure 1. The input control

current through the electromagnetic coil (motor

coil) creates forces at the ends of the armature,

causing the torque motor to move the rigid flapper

assembly toward one of the nozzles. The movement

of the flapper between nozzles creates a pressure

differential between the two ends of the spool

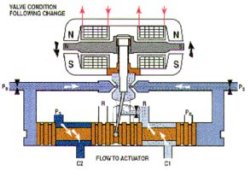

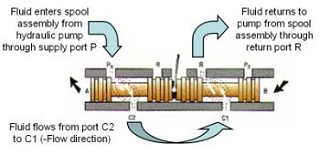

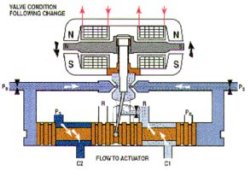

(shown in Figure 2).The spool then moves and opens

the pressure port (P), control ports (C1 and C2),

and the return port (R), allowing hydraulic fluid

to flow through the servovalve (shown in Figure

3).

|

Figure

1. Servovalve

cut-away view

|

The build-up of load differential pressure

creates a feedback force on the spool. Since a servovalve

controlled hydraulic actuator can produce an extremely

large and damaging load, it is imperative that the servovalves

perform accurately to their specifications.

Figure

2. Torque

motor moves

rigid flapper assembly

|

Figure

3. Hydraulic

fluid flows

through the servovalve

|

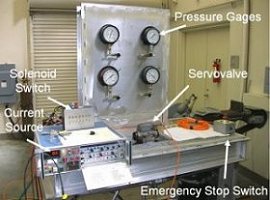

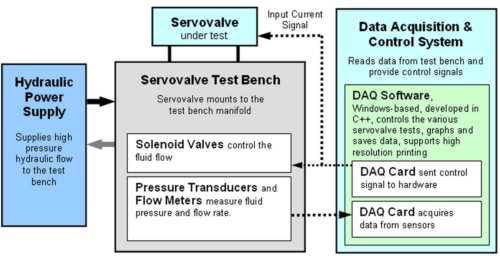

Boeing donated a United Filco high-capacity

hydraulic power supply to Seattle University for use

in this project. The partially completed servovalve

test bench and a Windows-based computer system were

also provided for use throughout of the project. The

goal of the project was to integrate these components

into a fully-functional servovalve testing and calibration

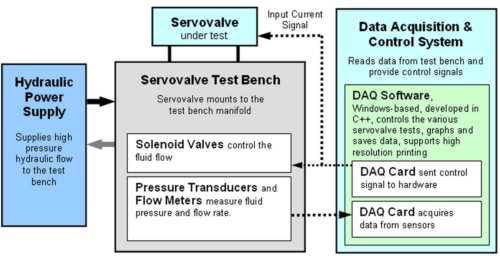

system. Figure 4 shows the general overview of the calibration

system. The servovalve under test is placed on the servovalve

test bench while a computerized data acquisition and

control system controls and acquire data from the servovalve

tests. The specific tests and components will be discussed

in later sections.

Figure

4. Servovalve calibration system overview

1.

Hydraulic Power Supply

Boeing donated a United Filco high-capacity hydraulic

power supply, shown in Figure 5, to Seattle University

for use in the development of a servovalve calibration

system. The hydraulic power supply, weighing 3,000 pound

and occupying a floor footprint of 4’ by 8’,

had an electrical requirement of 440 V at 88 A (38.7

kW). ME 5.3 transported the hydraulic power supply from

Boeing’s facility to Seattle University. An electrical

power supply and connectors (rated 480 V at 200 A) were

special ordered and installed for the project. The hydraulic

power supply is capable of delivering a line pressure

of 3,000 psi and a sustained flow rate of 35 gpm.

Figure

5. The

hydraulic power supply

|

Figure

6. Servovalve test bench

|

2.

Servovalve Test Bench

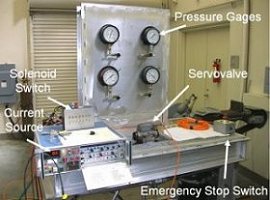

ME5.3 also transferred the 850 pound servovalve test

bench to Seattle University. It has never been pressurized

or tested at Boeing. ME 5.3 completed leak tests on

all hydraulic fittings and troubleshot the equipment

for subsequent use. A photograph of the top portion

of the servovalve test bench is shown in Figure 6.

Figure

7. Servovalve

test bench schematic

|

Figure

8. Servovalve ports

|

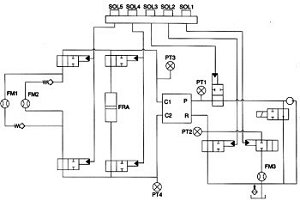

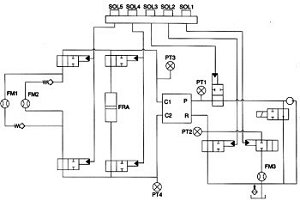

A schematic diagram of the test bench is also shown

in Figure 7. The solenoid valve bank SOL1~5 (top of

the figure) in Figure 7 manages the direction of fluid

flow to and from the servovalve. Three flow meters measure

flow rates in the lines. The three flow meters are marked

as FM1, FM2, and FM3. As indicated on the schematic,

the flow meters measure the lines “+Flow,”

“-Flow,” and “Leakage Flow”

respectively. Two pressure transducers, marked PT1 and

PT2, monitor pressures in the “pressure supply”

line P and the “pressure return” line R.

Two other pressure transducers PT3 and PT4, shown in

the schematic, are not physically attached to the testing

bench. Frequency response actuator (FRA) features a

low-mass and low-friction piston that moves with cyclic

alternating pressures at its ends.

Attached

to a linearly-variable differential transducer

(LVDT), the FRA is used to determine the useable

range and the frequency response of servovalve

controlled hydraulic actuator. The four-port servovalve

manifold is shown at the center of Figure 5. Ports

leading to pressure supply line (P) and return

line (R), as well as the two control ports (C1

and C2) are clearly marked. The manifold on the

test bench adhere to the standard manifold geometry.

The reciprocating ports on the servovalve are

shown in Figure 8. Ports leading to pressure supply

line (P), return line (R), as well as the two

control ports (C1 and C2) are clearly marked in

the identical manner as those on the test bench.

3.

Computer System

Boeing provided ME 5.3 with all the necessary

computing equipment and software for the project.

A rack-mounted Pentium 4 computer system with

Windows XP Professional operating system, along

with Microsoft Visual Studio, was used to develop

the control and data acquisition software. The

National Instruments data acquisition card (DAQ),

installed in the computer, provided analog and

digital inputs and outputs for data acquisition

and control of the servovalve calibration tests.

The near-completed computer rack, with the computer,

hardware interface, and DAQ breakout panel is

shown in Figure 9. |

Figure

9. Data

acquisition

and control system

|

Next Page

- Research

|

|