Project

Overview

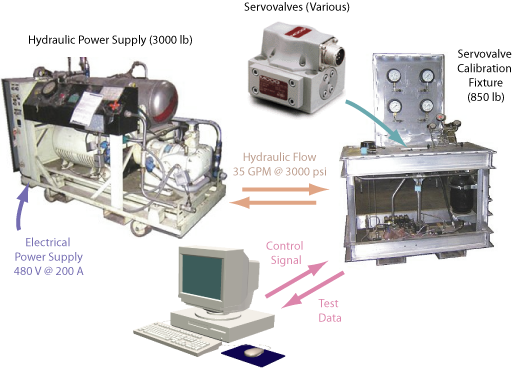

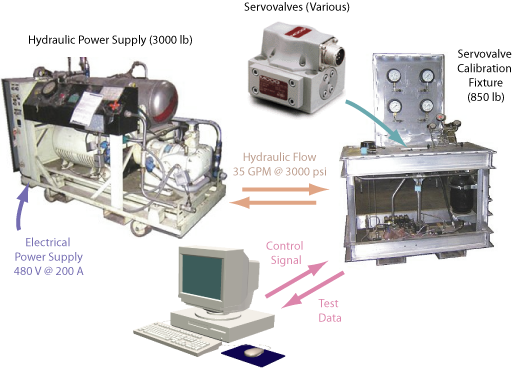

The Commercial Airplane Group of The Boeing

Company is the leading supplier of commercial aircrafts

flown throughout the world. At its testing facility

near Boeing Field in South Seattle, servovalves are

used in a number of testing applications for commercial

aircraft components. A servovalve is a device that uses

a small amount of electrical current (~15 mA) to precisely

control a large amount of hydraulic power (~100 horsepower).

Because the servovalves control such massive amount

of hydraulic fluid flows, it is vital that they perform

with accuracy and precision. Currently if a servovalve

is suspected of malfunctioning, it is sent to the servovalve

manufacturer for testing and calibration, resulting

in possible unwanted downtime for that specific testing

application. An in-house testing system and procedure

would reduce such a downtime.

The Boeing Company is seeking a fully

assembled servovalve testing fixture and procedure to

analyze and evaluate the performance of the servovalves

in-house. The required measurements are the proportional

no-load flow rate and blocked port pressure from the

servovalve as a function of the input current. A servovalve

must also produce a specific output flow magnitude corresponding

to a correct current frequency. Both control and data

acquisition for the calibration tests should be fully

computerized.

|