|

MEGR

493

Advanced Engineering Materials

Description:

Composite materials: analysis, design

and manufacturing. Selection of materials in

mechanical designs, engineering polymers, biomaterials

and nanomaterials. (spring, odd years*)

Who

takes it: Junior/senior mechanical

engineering students interested in the topic,

satisfies mechanical engineering elective requirement.

(elective) |

|

Pre-requisite:

MEGR 350 Materials Science, CEEGR 221 Strength

of Materials, MATH 233 Linear Algebra, or instructor's

consent*

Course

objective: Understanding and the application

of modern advanced materials (mainly composite materials)

in mechanical engineering design (7 weeks). The course

also exposes students to design methodologies and

materials of current interest to mechanical engineers

(3 weeks).

Textbook:

Laminar

Composites by George H. Staab, Publisher:

Butterworth-Heinemann; (1999); ISBN: 0750671246 (Amazon

listed at $67.95)

Evaluation:

One two-hour final exam (40%), two hourly

exams (20% X 2), homeworks (15%), pop-quizzes (4%),

and professionalism (1%).

Topics

Covered:

- Composite

materials introduction, background, selected manufacturing

techniques (2 lectures)

- Generalized

stress, strain, and constitutive equations (4

lectures)

- Analysis

of unidirectional composite lamina (stiffness matrix,

stress transformation, plane stress) (4

lectures)

- Composite

lamina failure theories (max shear, max strain,

Tsai-Hill max work, Tsai-Wu tensor theory, buckling)

(4 lectures)

-

Composite laminate analysis (classical lamination

theory, failure analysis, design for application)

(6 lectures)

- Selection

of materials in mechanical design (3

lectures) time permitting

- Engineering

polymers (2 lectures)

time permitting

- Biomaterials

(2 lectures) time

permitting

- Nanomaterials

(2 lectures) time

permitting

Special

Note:

- The

course is mathematically rigorous.

- Heavy

use of matrix algebra. The use of computation software

may become necessary. The deparment will provide

MATLABTM, but

you can use other softwares or even write your own

C++ solver codes.

- May

arrange a tour to a composite manufacturing or testing

facility in the Seattle area.

Sample

Lectures:

References:

Links:

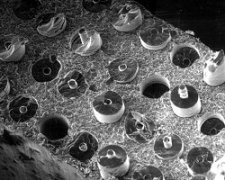

Figure:

100x

SEM micrograph of a fracture surface on a titanium

matrix composite (reinforced by large diameter SiC

fiber) after fatigue failure. This photomicrograph

was taken by me in 1995.

*

check with the instructor

|

|

|